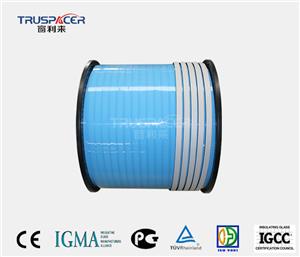

Truspacer Insulating Glass Warm Edge Sealing System

Truspacer Insulating Glass Warm Edge Sealing System

The products of our company Truspacer® have passed IGCC certification in the United States, EN-1279 testing in Europe, Qinhuangdao national glass quality control center testing, and ISO9001 quality system certification. Our company has the right to import and export, with a number of utility model patents. After more than 20 years of development, the company's products are exported to more than 50 countries and regions, the company's staff will be high quality products, quality professional services and friends from all walks of life mutual benefit, common development.

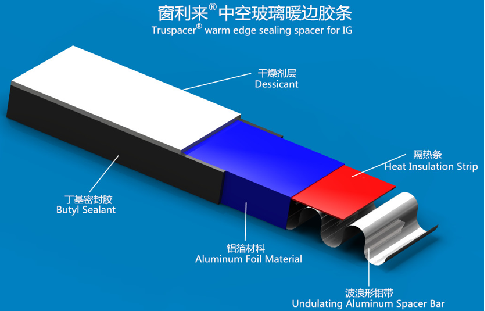

The main raw materials of Truspacer insulating glass warm edge rubber include butyl rubber, polyisobutylene, petroleum resin, molecular sieve and carbon black, etc. Chooses high grade raw material to produce products of our company, with a high level R&D team as a technical support, the company equipped with professional testing personnel and equipment for raw materials and finished products testing, each batch products are need to be strict inspection, to ensure product quality meet the requirement of national standard, and we are always adhering to the "the best warm edge strip products dedicated to the world" of the enterprise mission, adhere to conscience, awe, rest assured products.

The basic features of Truspace

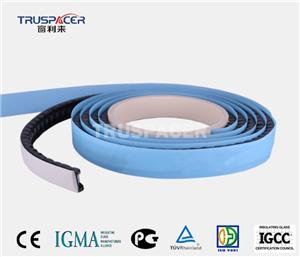

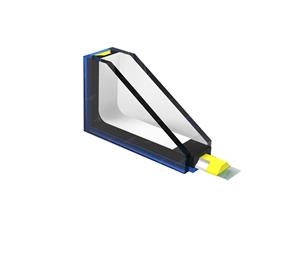

1. Truspacer strip on both sides of the use of butyl rubber and has a permanent viscosity of polymer mixture of polyisobutylene. Butyl rubber is lowest, water vapor permeability of rubber and polymer polyisobutylene strong persistence, so Truspacer strip more able to for a long period of time to ensure the service life of insulating glass over 30 years.

2. Gray part is made up of 3A molecular sieve and mixture of butyl rubber, most used in the market now is 4A molecular sieve, the difference is: 3A molecular sieve absorption of water molecules of air only, and 4A molecular sieve absorption of water molecules in the air not only, also absorb substances such as methanol, nitrogen, carbon dioxide, sulphur dioxide, internal pressure increases, this will cause hollow glass glass more easily affected by stress and crack. Since the 3A molecular sieve only absorbs water molecules, the negative pressure inside the insulating glass is reduced and the explosion of the insulating glass is reduced. Ensure the insulating glass at minus 40 degrees no dew, frost, moisture absorption more durable.

3. Aluminum foil material: The aluminum foil material wraps the aluminum strip and the polymer heat insulation strip together, so that the contact between the rubber strip and the glass becomes a surface contact. In the pressing process, the accuracy of the pressing size can be ensured and the sealing of the rubber strip can be improved. At the same time, the aluminum foil film also prevents water vapor from penetrating into the inside of the hollow glass, ensuring that the inside of the hollow glass is dry.

4. Polymer thermal insulation strips: First, the polymer thermal insulation strips make the surface of the produced strips more straight and make the appearance of the strips more beautiful. At the same time, the good low conductivity further reduces the K value of the edges and makes the strips tensile. Second, the compressive strength is enhanced to ensure that the rubber strip is not deformed by the negative pressure, and effectively prevents the external water vapor from penetrating into the inside of the hollow glass, thereby ensuring the drying of the hollow glass.

5. Wavy aluminum strip: The width of the wavy aluminum strip or polymer material is 4.8mm. When used in combination with the aluminum foil film, it strengthens the supporting force of the glass and makes the inside of the manufactured hollow glass less prone to compression during stacking.