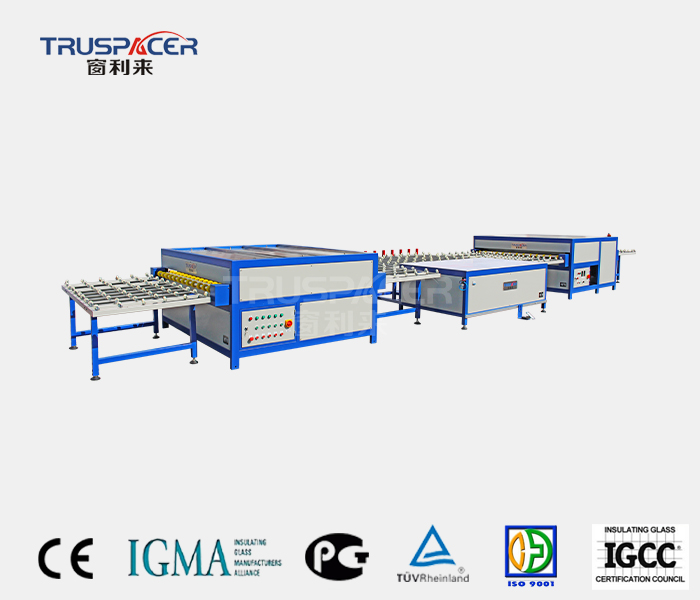

Truspacer Warm Edge Insulating Glass Production Line Configuration

Truspacer Warm Edge Insulating Glass Production Line uses first-class and well-known brand components, therefor our insulating glass equipment is trustworthy and popular around the world.

Truspacer Warm Edge Insulating Glass Production Line Configuration

1、Washing and drying machine

2、Air floating machine

3、Rolling over machine

4、Hot press machine

5、Gas filling machine (Optional if required)

6、Two-component glue coating machine(Optional if required), among them, insulating glass hot press is a must.

The layout of a single production line is the preparation area, processing area, semi-finished product inflatable secondary glue area, finished product inspection area and finished product area.

The minimum size of a single production line processing area is: 15 meters long and 5.5 meters wide. If a standard lamination room is established, the location of the lamination room should be between the glass exit of the washing machine and the inlet of the hot press. The minimum size should be: 5 Meters, 6 meters wide, dehumidifiers or air conditioners should be installed in the assembly room.

The minimum size of the two-line processing area is: 17 meters in length and 8 meters in width. The dimensions of the lamination room are: 7 meters in length and 8.5 meters in width. The dehumidifier or air conditioner should be installed in the lamination room.

1、1800 Washing and drying machine

Conventional power supply: 380V, 50Hz (3-phase, 4-wire system), special power supplies can be customized.

Power: 8.56Kw

Size: 1800mm,washing speed 1.7~5m/min;

Minimum size of cleaning glass 450mm, maximum width 18mm, glass thickness ≤ 5mm;

Type of glass that can be cleaned: white glass (LOW-E requires brush replacement)

Glass drying: Wind heating.

Attention:

1. If hot water cleaning is needed, special customization is required.

2. before using the equipment, be sure to soak the suction roller.

3. If you need to speed, only after starting, stop can not speed.

2、1800 Air floating machine

Conventional power supply: 380V, 50Hz (3-phase, 4-wire system), special power supplies can be customized.

Power: 1.1Kw

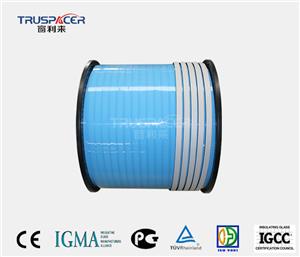

The operating table is a device for placing sealing spacer. The size of the table is 2000×1300mm, which is flat and smooth. It is made of wear-resistant materials. The surface is spliced due to the specifications of the materials.

The countertop has a blower and air-float function, it uses a pneumatic ventilation device to achieve the blowing and sucking function of the table surface, so that it can better help workers to paste the sealing spacer.

3、1800 Rolling assembly station

Air pressure: 0.6MPA

Mainly used for the alignment of insulating glass, the equipment in the production of insulating glass process to solve the problem of poor alignment of large glass, turn over the glass that has been attached with the sealing spaer, against the position of the right angle baffle post, convenient for the alignment of the second piece of glass.

Using universal wheel table, pneumatic turnover.

When the rolling assembly station is operated, the cylinder can be controlled by manual switch, so that the table can be turned over and the turning action is smooth.

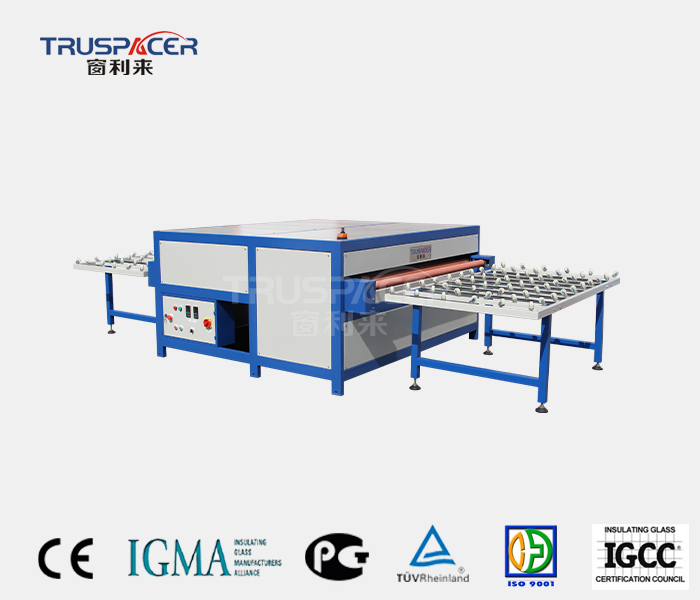

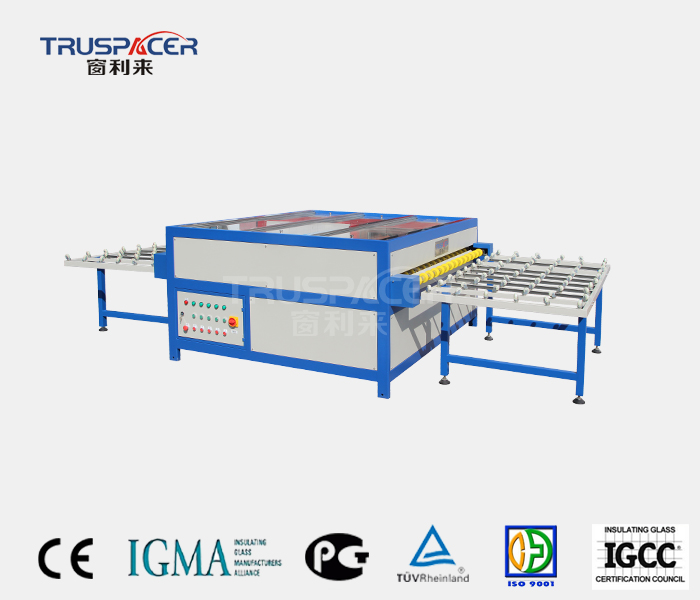

4、1800 Hot press machine

Conventional power supply: 380V, 50Hz (3-phase, 4-wire system), special power supplies can be customized.

Power: 27Kw

This is a necessary equipment for sealing spacer type IG. The minimum hot-pressed glass is 300×300mm and the maximum width is 1800mm. It is heated by a halogen lamp and progressively pressed. The size of the two sides is fixed.

Effective speed: 1.7-5 meters/minute, using stepless frequency conversion.

Thickness of laminated insulating glass: ≤ 50mm.

Heating scheme: Domestic halogen lamp 22Kw is used to control the switching of 1/2 halogen lamp respectively.