New Techniques of Modern Door and Window Sealing

New Techniques of Modern Door and Window Sealing

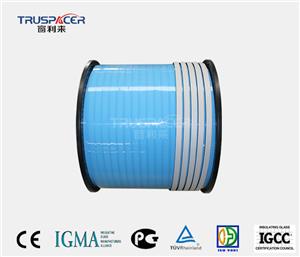

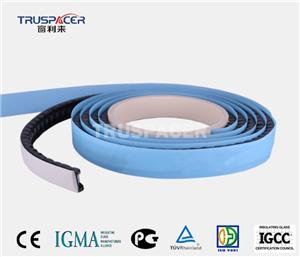

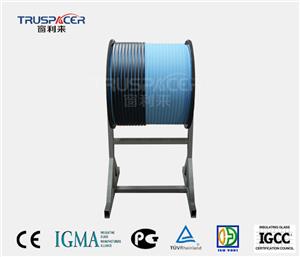

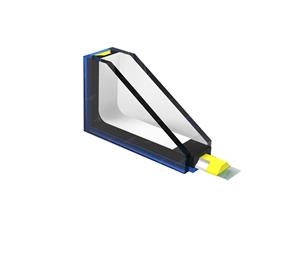

Truspacer is a warm edge spacer system ideal for high-volume production of double and triple pane insulating glass, it is preassembled with butyl sealant, 3A molecular sieve, undulating aluminum spacer bar and heat insulation strip and so on, it can replace the traditional IG production mode and greatly improve production efficiency.

The materials used in Truspacer warm edge spacers are also the highest quality in the industry. For example, butyl sealant, 3A molecular, etc.

Butyl sealant: It is a one-component, environmentally friendly non-curing self-adhesive sealant processed from butyl rubber through a special process, and is also specially designed for the characteristics of the blade manufacturing industry, which can be widely used in automotive, construction, industrial and other uses. The main advantages are as follows:

1.Single component, easy to use, good stability in the tempreature range of -40℃~-120℃;

2. Non-curing, non-corrosive to metals, coated glass, concrete, marble, granite and other materials, widely used;

3.Can withstand certain type changes and have plasticity;

4.UV resistance, ozone resistance, water resistance, chemical corrosion resistance;

5.Does not contain any solvent, safe and environmentally friendly;

6.Easy to use, material saving;

7.The service life of more than 20 years can be stored for a long time.

Butyl sealant is a sealant with isobutylene polymer as the main material, which is one of the four most consumed selants in the world. It has excellent weather aging resistance, heat resistance, acid and electrical insulation properties. It can be divided into vulcanized type, non-vulcanized type and hot melt type. Among them, the non-vulcanized type can be divided into solvent volatile from is made by mixing, shearing and dissolving; Preformed strips are made by mixing and extrusion; The sealing paste can be manufactured by dissolving or grinding by a three-roller machine. Butyl sealants are widely used in various machinery, pipelines, glass installation, cable joints and other seals and buildings, water conservancy projects.

Hot melt butyl sealant is a one-component, solvent-free, non-foggy, non-vulcanized, permanently plastic first sealant for insulating glss based on polyisobutylene rubber. Hot melt butyl sealants maintain their plasticity and tightness over a wide temperature range without cracking or hardening on the surface. It has good adhesion to glass, aluminum alloy, galvanized steel, stainless steel and other materials. Due to its exstremely low water vapor transmission rate, it can be combined with elastomeric sealants to form an excellent moisture resistant system.

Features:

Good sealing effect, easy quality assurance;

No curing period required, saving floor space;

It is an environmentally friendly product, no waste in use, and the environment is clean;

Save your time, raw materials, staff, reduce production coasts.

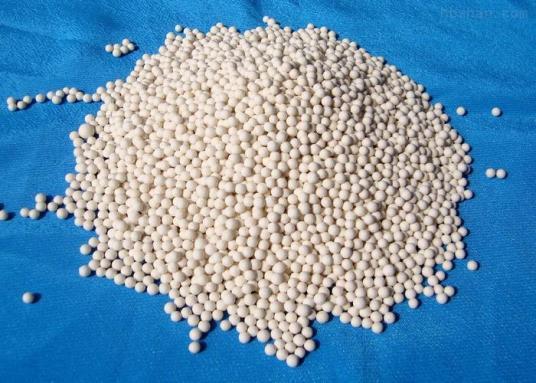

3A Molecular: The pore size of 3A molecular seive is 3Å; mainly used to adsorb water, do not adsorb any molecules with a dimeter greater than 3Å, according to the characteristics of indusctrial applications, molecular sieve has fast adsorption speed,regeneration times,crushing strength and anti-pollution ability, improve the utilization efficiency of molecular sieve and extend the service life of molecular sieve, is the petroleum and chemical industry gas-liquid phase deep drying, refining, polymerization necessary desiccant.

Effective pore size: about 3Å(1Å=0.1nm)

Application

1.Drying of various liquids( such as ethanol)

2.Drying of air

3.Drying of refrigerant

4.Drying of natural gas and methane gas

5.Drying of unsaturated hydrocarbons and cracking gas,ethylene, acetylene, propylene, butadiene